How wonderful to have a trap that “just works.” Substituting a new regulator for the original Defender and Liberty regulators has resulted in a so-far perfectly stable system, without the “abnormal combustion” problems that had been plaguing the 2002 Mosquito Magnet Defender for over a year now, or longer.

The first regulator was a high (140K) BTU with a no attached hose, similar to the original regulators. It is larger and more expensive than the standard replacement regulators, including the one used on the Mosquito Magnet Patriot. However, it had a removable cap that possibly supported adjusting the output pressure, and the existing hose could just screw in via an adapter to match the thread sizes. The parts are Marshall Excelsior MEGR-230 with an Acme Nut to 1/4″ M NPT to attach to the tank, and a 1/4″ F to 3/8″ M NPT fitting to match the existing hose. The total cost was about $27, higher than the standard replacement units. The cord comes out the back instead of the side, which sticks out and looks a bit awkward. This regulator provided almost exactly 11.0 inWC pressure.

However, when the pressure probe was attached, the rush of propane into the small bottle did set the combustion to the abnormal, rough mode. The trap did not recover on its own within a minute.

The standard regulators come with permanently attached hoses with a 3/8″ F flare connector. The hose is a bit larger than the original, but the connector is much larger, and requires another large adapter to screw into the Defender valve assembly. Thanks a lot, safety people. Holding the hose and adapter against the Defender, it looks like the fittings are too large to fit inside the case vertically, and the large nut may not fit through the case hole. This may be investigated during the off season, but using the standard hose doesn’t look promising, especially considering that the Mosquito Magnet Patriot uses an external adapter on a short cable to connect to the valve inside the trap.

The work-around is to use a 3/8″ M Flare to 1/4″ F NPT coupling ($4), and tie the two hoses together, like the Patriot, except that the original hose is now much too long for a neat installation. Perhaps the hose can wrap around the tank.

Another approach, used in the Patriot, is to shorten the hose from the Defender and attach a new 3/8″ male flare fitting. Alternately, remove the 3/8″ female flare fitting and attach a new 1/8″ male fitting. Acquire a hose kit with barb fittings, ferrules, and a vice-grip-looking crimper for about $50, and away you go (but no leaks allowed). This is too much for me.

The IGT 2.8 KPa 2′ Hose Regulator ($10, total $14) used in the Patriot was installed. The unit is rough and dull, but is configured similarly to the original regulator. It put out ~10.5 inWC pressure, but provided a 95°C exhaust temperature rise for 80 minutes with no problems. It was taken out of service to test the third regulator.

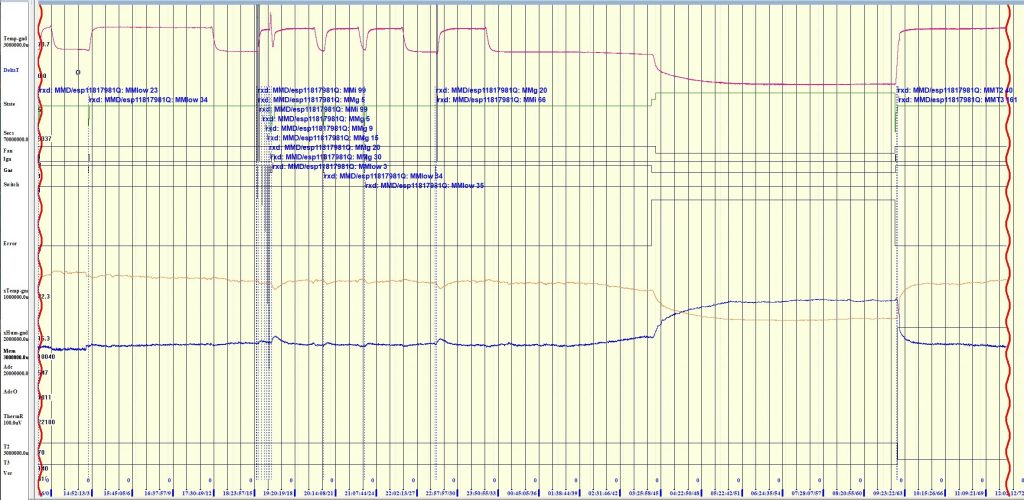

The last test used the Dozyant Vertical 2′ Hose Regulator ($10, total 14). This unit is shiny smooth. The hoses dangle and wrap as the other regulator. It puts out close to 11 inWC pressure. However, after a little less than an hour running, the temperature rise above ambient went from 95°C to 100°C, then the exhaust temperature dropped to 80°C, just like the old defective regulators. Upon restart, the unit reached a 100°C exhaust rise from ambient, then after a little more than an hour, went to 105°C above ambient only to drop to 80°C (55°C above ambient). This repeated failure disqualifies the Dozyant. The unit was replaced with the IGT unit for further testing.

All of these regulators provide a relative pressure output, that is, the output pressure of 11 inWC is relative to the atmospheric pressure. So if the atmospheric pressure is 30.13 inHg or 409.24 inWC, and the pressure at the Schrader valve is 30.89 inHg or 419.49, the regulator output is the difference, here 10.25 inWC, which is close (but not that close) to the rated 2.8 KPa (kilo-Pascal) or ~11.4 inWC specified for the IGT regulator.

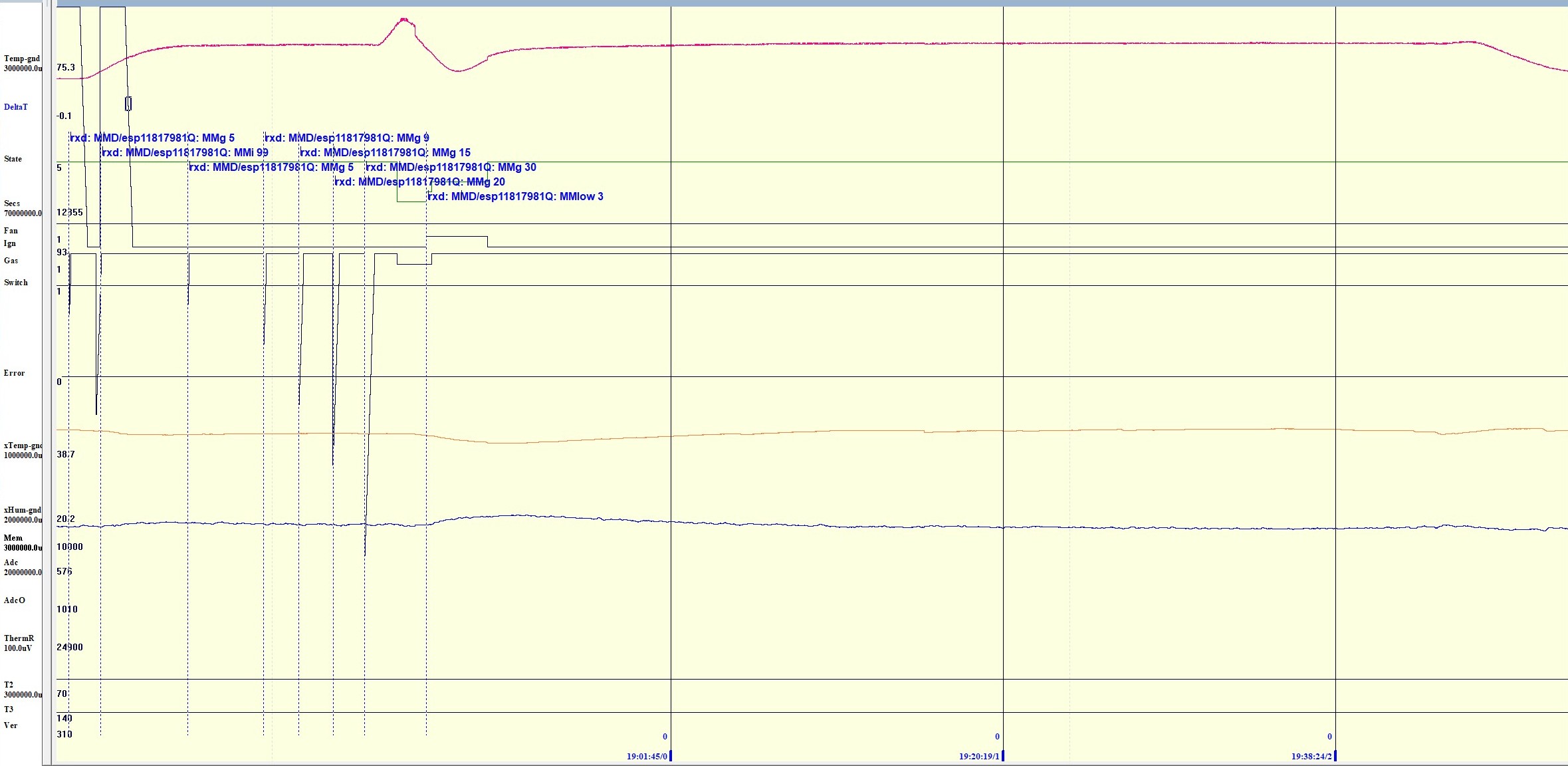

After almost 3 hours, it was time to remove the exposed battery operated pressure sensor. The IGT trap was running at 115.9°C exhaust with ambient air intake 17.8°C and 70.1% relative humidity when the pressure sensor was removed from the Schrader valve. The temperature difference of 98°C was a bit high, but so was the humidity, which makes the air mixture less dense, and the expected temperature rise higher.

The absolute pressures were 419.69 inWC attached and 409.70 (30.17 inHg) removed for a difference of 10 inWC. This is more than 10% less than 11.4 inWC. The 30.17 inHg is what one might call “mean pressure” discussing weather: in the last month, the pressure ranged from a low of 29.71 to a high of 30.59. It would be better if the output pressure were closer to spec or at least 11 inWC, but perhaps the 5%-10% difference will not be significant, as long as the pressure is constant and not irregular. On the plus side, it may conserve propane.

However, like the more expensive unit first tested, removing the pressure gauge caused the trap to enter the dreaded “abnormal combustion” phase. The exhaust temperature difference rose to 121.7C (105°C difference), then fell to below 70°C, and the trap entered the fault state. All of this was caused by a momentary dip in pressure from quickly removing a gauge from a Schrader valve. We cannot expect any regulator at the end of a hose to compensate for a sudden pressure change next to the flame, so the removal does not reflect badly on the regulators, but does demonstrate the importance of maintaining a steady, constant pressure.

Sudden pressure fluctuation is now the prime suspect in triggering the abnormal combustion. This characteristic is not very important for barbecue grill regulators, which average the flame over a relatively long time. We shall see how this unit performs on the Defender, which requires a very steady flow to maintain its small flame. A test failure does not mean that the unit is defective for its intended use, it just means it didn’t work well in the Defender. We are depending on an unspecified behavior of a mass market commodity consumer device, not the safest strategy.

The pressure sensor is capable of over 100 samples per second pressure acquisition from the chip and an unknown but sufficient rate from the software, but transmitting the data is another challenge. Properly designed, the system is likely fast enough to detect problematic pressure fluctuations, however, getting the pressure sensor working and recording high speed looks like a winter project. We would also need an quick response “abnormal combustion” detector. Audio or vibration sensing might work. Perhaps, by some stroke of luck, none of this will be necessary.

To achieve relative regulation, the regulator needs a port (hole) to measure the atmospheric pressure. These ports are subject to contamination. The regulators themselves typically have instructions to install under protective cover. Of course, no one does that, but from now on, it may be a good idea to follow the directions. We are really looking for that “just works” magic, and a “protective cover,” like an iPhone case, adversely impacts the industrial design of the system.

So at this moment, the Dozyant unit failed the Mosquito Magnet Defender test, and the IGT unit is now under test. Stay tuned for test results. If the IGT unit fails soon, this paragraph will be updated with the results. One update has already been made. Otherwise, a new entry will be posted.