MM Defender IOT Controller Construction Details

Contents

- 1 MM Defender IOT Controller Add-On Construction Details

- 1.1 Hazard Warning

- 1.2 Photos

- 1.3 Basic Steps

- 1.3.1 Assemble Tools and Supplies

- 1.3.2 Test and Fix the Original Controller

- 1.3.3 Acquire Materials

- 1.3.4 Set up Development PC & Software

- 1.3.5 Attach Header Pins to the HTU-21D

- 1.3.6 Flash and Test the Module(s)

- 1.3.7 Build the Wiring Harness

- 1.3.8 Modify the Controller PCB

- 1.3.9 Attach the Harness

- 1.3.10 Install Modified Controller into Trap

- 1.3.11 Move Trap to Operating Location

- 1.3.12 Final Test

- 1.3.13 Monitor from PC and Phone

- 1.4 System Requirements

- 1.5 System Design Description

MM Defender IOT Controller Add-On Construction Details

This is a rather large topic under construction. Current progress is about 40%.

Recent posts on the Mosquito Magnet Forum have described a replacement controller that a skilled DIY (Do It Yourself) person can build and install. Poor manufacturing quality control plus harsh outdoor environments has caused some original controllers becoming faulty with age. Additionally, it is quite difficult for DIYers with technical expertise to troubleshoot a non-working trap with just the original controller, even with troubleshooting instruments. What is missing is a mechanism to monitor and troubleshoot these devices so they can keep working into the future. The MM Defender IOT Controller article describes an effective approach, but is lacking details on how to actually construct and implement the device. This article will supply more details. It is, however, necessary to discuss a few matters regarding this MM Defender IOT Controller Add-On design, which partially explains why this topic was not written earlier.

Hazard Warning

First, the Mosquito Magnet traps use propane gas, which is flammable, and therefore dangerous. The original trap designers took great pains to make sure the trap would be safe. This is why the trap shuts down if everything is not "just so." While frustrated users being bitten might say that the trap is overly conservative and unnecessarily cautious, DIYers have not done the extensive analysis customary for a manufacturer of a potentially dangerous device.

Making and deploying a substitute controller, or any modification of a dangerous device, can be regarded as a risky or even reckless action. If something goes wrong, and there is an explosion, poisoning, or other calamity resulting in loss of life and limb, or property damage, do you want to have had a hand in the chain of events that possibly or even arguably might have caused it?

Second, the construction, modification, and installation requires tools and instruments plus experience with PCBs and micro component soldering. Those without the right tools or skills will find this project too difficult. Once modified, it is relatively easy but not trivial to revert to the original controller. If the modified system does not work, you may be stuck.

This design is an Add-On to the original controller. Accordingly, other than the original PIC micro-controller, the original controller must be working because the IOT Controller Add-On just substitutes for the PIC. However, it is the failure of some of the parts of the original controller that might have caused the problem in the first place, and fixing those issues could restore the original controller to functionality. If the trap still does not work reliably, capable experts willing to assume the risk might choose to use the add-on controller to help identify those issues.

Third, the controller is an experimental device intended for use by experts to troubleshoot a non-working trap, and not as a permanent replacement for the original controller. As presently implemented, it lacks important features required for a permanent deployment. Some of these are: adequate mechanical support (mounting to the device), weatherproofing, and, of course, safety and functionality certification and validation.

Currently, the controller is supported only by the wires connecting it to the original controller PCB. Because it is not fully insulated, it must be positioned just so to avoid shorting to the trap metal parts. Although electrical insulation and some weatherproofing could be mostly jury-rigged by covering the controller with a plastic bag, this is not a permanent solution. This unprotected device does not and will not survive condensation and contamination from the elements.

Although wireless remote control makes physical contact with the device unnecessary, as an experimental device, it is desirable for it to be quickly and easily accessible for updating or substitution. This requires removing the catch basket and top cover. It is not easy to remove the top cover screws, so to avoid biting mosquitos, some may choose leave the screws out, which then results in yet another potential hazard.

Under no circumstances do we want anyone to endanger any life or property. Any servicing or modification of the trap is a dangerous undertaking. You should label any modified trap with a warning.

Remember, the add-on will not work reliably over the months or years due to lack of mechanical support and weatherproofing. Once your trap is working reliably, you should uninstall the controller add-on and revert to the original, unless you are engaged in active development, are willing to assume the risks, and willing to maintain and repair the modification as it corrodes or otherwise deteriorates.

These remarks, of course, apply to all DIY modifications, not just this one, which is intended only for troubleshooting and development. Finally, please be cautious, even if you improve upon the design.

Photos

Nothing to be too proud of here. Some burned insulation, scattered wires, no strain relief anywhere. Click on a picture to see it larger.

There are 10 wires connecting the Add-On headers to the original controller, and 4 more connecting to the optional Temperature/Humidity sensor, which itself is flying off the Add-On. Nice work! Observe the lack of strain relief and mechanical support, other than the 10 wires. This hack job is dis-recommended for long-term use. Note how easily the NodeMCU module or its uninsulated pins can come into contact with the metal trap parts. Be careful, or insulate, mount somehow, or all three.

Generally, the connecting wires are soldered to the most rugged attachment points available, through hole terminals if available, or soldered to a component and its pad if not. However, 2 wires are soldered only to pads, and these are fragile. Some notes:

- C4 is effectively removed by cutting the foil to it (to the right of the middle white wire, a bit hard to see)

- On the board, the PIC controller has been completely removed (because it was fried). Otherwise, unsolder and lift pin 4 from its pad on +5v, and solder a very thin 1 strand jumper between the lifted pin and the adjacent pin #5. This sets the MCLR/ signal low, which effectively disconnects the PIC.

- Note the jumper between pin 14 and the top of R5 or pin 11. This connects VDD to R5 20k0.

- VDD is disconnected from +5v by cutting a foil on the bottom of the PCB (not shown).

- VDD is connected to +3.3v from the NodeMCU via the left orange wire.

- The right hand white and orange wires connect to the original ground and +5v rails near the electrolytic cap. These go to the rear or left hand side connector pins.

- The single pin white wire connects the ADC input to the bottom of R5.

- The WiFi antenna is on the front of the NodeMCU, and the USB connector is on the back. There is also a reset and a flash button, and 2 status LEDs.

Basic Steps

- Thoroughly read the MM Defender Controller and MM Defender IOT Controller wiki pages.

- #Assemble Tools and Supplies

- #Test and Fix the Original Controller

- #Acquire Materials

- #Set up Development PC & Software

- #Attach Header Pins to the HTU-21D

- #Program and Test Module(s)

- #Build the Wiring Harness

- #Modify the Controller PCB

- #Attach the Harness

- #Initial Test Outside Trap

- #Install Modified Controller into Trap

- #Move Trap to Operating Location

- #Final Test

- #Monitor from PC and Phone

Assemble Tools and Supplies

You will need the following tools, equipment, and supplies:

- 10x (opt. plus 50x) Stereo Microscope with illumination to clearly see what you are doing.

- Soldering iron with micro tip.

- Solder, solder flux, fine solder wick, PCB cleaner, alcohol, and brushes for cleaning.

- DeOxit or similar for cleaning switch and connector contacts.

- Micro tweezers for surface mount device (SMD) placement and manipulation.

- A fine gauge (diabetes) medical syringe is helpful for prying and scraping.

- Volt-Ohm Meter (VOM) with suitable test leads.

- Clip leads for testing, plus a 1k or so resister to force the driver transistors on.

- Oscilloscope, single or dual channel, calibrated, with probes. 10 MHz or higher. 1 MHz might work with allowances, not tested.

- Diagonal cutter and wire stripper for fine (e.g., 24-32) gauge stranded wire.

Test and Fix the Original Controller

If the original controller is not working, or even if it is, it is a good idea to remove it, clean it, and inspect it thoroughly.

- The 3 standoffs holding the board will have become brittle with age. Be careful when removing the board from the standoffs, and press the release tab on the component side before very gently pulling the board out. If you break a standoff, you can replace it (Richco SCBS-16-01), or tap the body for an 8-32 stud. The same goes for the nylon thermistor bolt, it should be replaced every service time (8-32 x 1/2").

The PCB is lightly (inadequately) sealed with a sealer for weatherproofing. Accordingly, you have to scrape off the sealant to probe a pad.

- Measure the resistances of the fan (?? Ohms, although it either works or it doesn't), igniter (0.9 - 1.4 Ohms), solenoid (?? Ohms), and thermistor (200 kOhms). If these are either too low or too high, they must be replaced.

- Measure the resistance across C4. Disconnect the thermistor. Attach the VOM negative lead to the negative (ground) terminal of power supply filter cap C2 (large 3300 uF @ 25v) and the positive lead to J1 terminal 1. The resistance should be in the meg-Ohm range (this is from the PIC). If it is low (e.g., 20 kOhms), your controller is suffering from the "C4 PCB contamination" issue discussed on the controller wiki page. If low,

- Carefully unsolder C4 (ca 120 nf ceramic, was previously marked 150 nf). Remove the coating from the pcb in the vicinity of the pads. Thoroughly clean the PCB between the pads. Measure the resistance again until it is in the meg-Ohm range. Measure C4, then carefully strip and clean as necessary until infinite resistance is obtained. Build up a solder blob on each mounting pad. Solder C4 to the blob to allow space underneath for cleaning. Thoroughly clean and measure. When in the meg-Ohm range, seal the area with a PCB sealer. Use two coats.

- With the 'scope, measure the power supply voltages and ripple voltages. See that the ripples are symmetrical, and not too large for the D1 C2 +20v supply. The large bridge rectifier D2 has no filter cap, and will show all ripples. Attach the igniter and ground the J5 pin 2 lead to power the igniter, and see that the voltage does not just collapse. The RMS value should be appropriate for the 12 volts igniter. The igniter should light up, and be hot enough to ignite a propane torch. This also tests the power supply and long low voltage cord. If there is a problem with insufficient power, check the AC side of the supply to isolate the problem to the supply/cord or D2 rectifier bridge.

- Measure the +12 and +5v rails, they should be without ripple.

- Attach the fan, thermistor, switch, and gas valve solenoid. Power the unit again, and observe the low (ground) side of the Igniter, Fan, and Valve go from +12 to 0 volts as the driver transistors switch on. Check the switch LED to see that it flashes on power up.

If any of these tests fail, there is a problem with either the driver transistors, the controller, or the switch that must be fixed before the IOT Controller Add-On can be used.

- Check the switch terminal to see that it goes between +5v (off) and ground (on) when actuated. Make sure that wiggling the wires to the switch has no effect in either position.

- Use the 1 kOhm or so resister in series with a test lead connected to +5v rail (supply voltage) to test the driver transistors. (You may have to scrape a pad on (e.g., on C7) and possibly solder a small piece of solid wire to access this rail.). Measure the voltage across the fan, igniter, and valve terminals to see that it goes on when the 1 kOhm signal is applied to the gate or base of the driver transistors. If not, the driver is defective, or possibly the igniter, fan, or valve solenoid is shorted.

If these tests are passed, perhaps you have fixed the problem, and can use your trap as is, provided the controller works. Try it. If working, catch some mosquitos and stop here. If not, you can continue with the IOT Controller Add-On.

Acquire Materials

Per unit, the NodeMCU is about $6, the optional HTU21D is ~$4, and the header, the wires, and the heat shrink tubing are hopefully "lying around" somewhere. Of course, you will want to buy multiples.

- 1 or more ESP8266 ESP-12E NodeMCU modules, from any number of vendors, e.g., "MakerFocus ESP8266 NodeMCU LUA CP2102 ESP-12E Internet WiFi Development Board Serial Wireless Module." Cost about $12 for 2 (get 4).

- (optional) 1 or more HTU21D Temperature/Humidity module, e.g., "HiLetgo HTU21D Temperature Humidity Sensor Breakout Module I2C IIC 1.5V-3.6V." Cost about $7 for 2.

- 1 40 pin female header strip, e.g., "10 Pcs 40 Pin 2.54mm Pitch Straight Single Row PCB Female Pin Headers." You should already have these, but the cost of about $6 for 10 pieces, yields a lifetime supply.

- Several colors of thin (28-32) gauge, stranded, flexible, 200°C, very high quality hookup wire with high temperature PTFE or Teflon insulation, e.g., "Alpha 2840/7." This example uses white, red, blue, orange, yellow, violet, and brown. Try to "borrow" the short lengths of wire from a "friend," otherwise it could get expensive (e.g., $70 for 100' reel, each color) to buy wire for this project. Do not use stiff or cheap wire. It will break with handling, melt, or tear the PCB board. The colored wire in flat cable may be tempting, but is especially unsuitable. If you do use stiff wire, it must be well strain-relieved on both the PCB and header ends.

- Heat shrink tubing is useful for insulating the terminals on the rear or left hand side of the module.

Set up Development PC & Software

The most convenient tools are java apps. Also, there is a python module that downloads the lua environment onto a new NodeMCU.

- Install Java, if not installed.

- Connect the ESP-12E Module to the PC via USB. If necessary, install the CP2102 Drivers to create a new COM port.

- Download and install ESPlorer, a java Integrated Development Environment (IDE) for ESP8266 developers.

- Download and install mqtt-spy, a java MQTT client.

- Download NodeMCU Flasher for Windows or the python esptool.py.exe. There are many options available, pick the one you most prefer.

- Download a suitable MQTT client to your phone (e.g., MQTT Snooper).

Attach Header Pins to the HTU-21D

- Attach a 4 pin male header (included) to the board opposite the component side.

- Attach 4 of a 5 conductor female-female jumper cable to the pins of both units. The colors don't matter.

| position | color | net | NodeMCU |

|---|---|---|---|

| 1 | blue | cl | pin 26 D4(GPIO2) |

| 2 | brown | da | pin 27 D3(GPIO0) |

| 3 | white | - | pin 17 gnd |

| 4 | orange | + | pin 16 3.3v |

Flash and Test the Module(s)

Install the NodeMCU lua environment

- Go to NodeMCU Cloud build service and select the following 11 sub-modules:

adc, enduser_setup, file, gpio, i2c, mqtt, net, node, tmr, uart, wifi. Submit the build request, and come back later when the build is complete, and download the built binary.

- You may choose (why???) to download a development branch or a master branch.

- Flash the module to install the NodeMCU lua environment. For example, to install the version 11 development branch floating point version.

esptool.py.exe -p COM3 write_flash -fs 32m -ff 80m --flash_mode dio 0x00000 C:\mmdefender\Install\nodemcu-dev-11-modules-2018-07-21-20-46-15-float.bin esptool.py v2.3.1 Connecting.... Detecting chip type... ESP8266 Chip is ESP8266EX Features: WiFi Uploading stub... Running stub... Stub running... Configuring flash size... Flash params set to 0x024f Compressed 458752 bytes to 297898... Wrote 458752 bytes (297898 compressed) at 0x00000000 in 26.4 seconds (effective 139.0 kbit/s)... Hash of data verified. Leaving... Hard resetting via RTS pin...

- Open ESPlorer and select COM3 or whatever port the module is using. Press the module reset button. ESPlorer responds:

Formatting file system. Please wait... NodeMCU custom build by frightanic.com branch: dev commit: fd745e0981ca2c4d425c966334cef67180f0cb63 SSL: false modules: adc,enduser_setup,file,gpio,i2c,mqtt,net,node,tmr,uart,wifi build created on 2018-07-21 20:45 powered by Lua 5.1.4 on SDK 2.2.1(6ab97e9) lua: cannot open init.lua

Not opening init.lua is a good thing, because nothing is programmed into the unit yet. Pressing the FS Info button shows:

Total : 3447234 bytes Used : 0 bytes Remain: 3447234 bytes

A 3.5 mb empty file system onto which we will load the firmware.

Install the MM IOT Controller Software

- Download and unzip the latest software into a folder.

- For each file in the release, upload the file into the NodeMCU module.

- Press the right hand "Reload" button to display the files in the module.

- For each .lua file uploaded, except init.lua, right click the entry and select "Compile xxx to lc." The compiled files take less program memory, which is very scarce.

- Press and release the RTS button to reset the module, and notice the additional output after the "powered by Lua" sign-on, e.g.,

39024 'tmr.stop(6)' within 5 seconds to stop running

- You have 5 seconds to type "tmr.stop(6)" on the bottom command bar and hit send, otherwise the main controller program starts. You would do this to upload a modified source file and compile it for your next revision of the software.

Test the MM IOT Controller Software

Press and release RTS to restart the unit and wait for it to start. The following assumes you have connected the optional htu21d module, otherwise you will receive maximum external temperature and humidity readings:

39024 'tmr.stop(6)' within 5 seconds to stop running > 38176 starting system 30416 30472 25176 23712 15640 15984 Wifi... 12752 8896

These declining numbers are the number of free CPU memory. If the lua OS runs out of memory, it panics and restarts. Free memory is so important, it is reported every second as "M=#" below:

Temp=-43.7C (-43.7) at 0:0 F=0 I=0 G=0 S=0 E=0 T=25C H=46.6% M=9752 (9/9:18804706) R=70~140 B=-19.0 V=3.1 state = 0 was 7 at 1 (0) Temp=-43.7C (0) at 0:0 F=0 I=0 G=0 S=0 E=0 T=25C H=46.5% M=9584 (9/9:18804706) R=70~140 B=-19.0 V=3.1 Temp=-43.7C (0) at 0:1 F=0 I=0 G=0 S=0 E=0 T=25C H=46.5% M=8176 (9/9:18804706) R=70~140 B=-19.0 V=3.1 Temp=-43.7C (0) at 0:2 F=0 I=0 G=0 S=0 E=0 T=25C H=46.3% M=8200 (9/9:18804706) R=70~140 B=-19.0 V=3.1 Temp=-43.7C (0) at 0:3 F=0 I=0 G=0 S=0 E=0 T=25C H=46.2% M=8208 (9/9:18804706) R=70~140 B=-19.0 V=3.1

The first time, skip to #Configure the Wifi. After you set up the wifi connection, you will get

Connected to wifi as:(omitted) 9208 Starting Web Server... Connecting to: test.mosquitto.org:1883 User: Pwd: ID:11823997 Subscribing to: /test/MMD/esp11823997Q Ok Temp=-43.7C (0) at 0:4 F=0 I=0 G=0 S=0 E=0 T=25C H=46.2% M=6232 (9/9:18804706) R=70~140 B=0.0 V=3.1

At some point, the OS starts garbage collection, and the free memory rises to about 11 kbytes:

Temp=-43.7C (0) at 0:5 F=0 I=0 G=0 S=0 E=0 T=25C H=46.2% M=7320 (9/9:18804706) R=70~140 B=0.0 V=3.1 Temp=-43.7C (0) at 0:6 F=0 I=0 G=0 S=0 E=0 T=25C H=46.2% M=7304 (9/9:18804706) R=70~140 B=0.0 V=3.1 Temp=-43.7C (0) at 0:12 F=0 I=0 G=0 S=0 E=0 T=25C H=46.4% M=7312 (9/9:18804706) R=70~140 B=0.0 V=3.1 Temp=-43.7C (0) at 0:13 F=0 I=0 G=0 S=0 E=0 T=25C H=46.4% M=11304 (9/9:18804706) R=70~140 B=0.0 V=3.1 Temp=-43.7C (0) at 0:14 F=0 I=0 G=0 S=0 E=0 T=25C H=46.3% M=11344 (17/16:18804706) R=70~140 B=0.0 V=3.1 Temp=-43.7C (0) at 0:17 F=0 I=0 G=0 S=0 E=0 T=25C H=46.2% M=11352 (17/17:18804706) R=70~140 B=0.0 V=3.1

and so on. 11 kb is sufficient for normal operation.

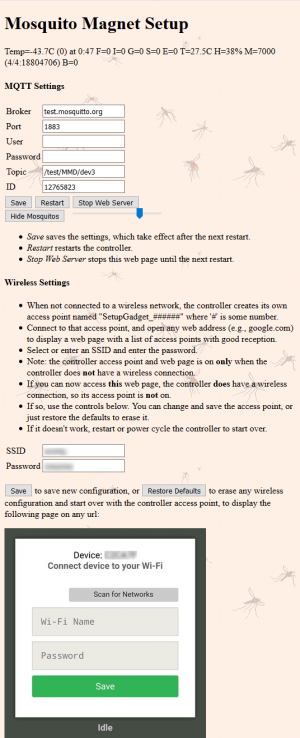

Configure the WiFi

When not connected to a wireless network, the controller creates its own access point named "SetupGadget_######" where '#' is some number.

- Connect to that access point, and open in a browser any web address (e.g., google.com or http://t.c) to display a web page with a list of access points with good reception.

- Note: the controller access point and web page is on only when the controller does not have a wireless connection.

- Select or enter an SSID and enter the password. The controller will try to connect and display the IP address it has received via DHCP (e.g., 192.168.1.32).

Configure the MQTT Client

- Open the controller's web page with the above address followed by :8080 (e.g., 192.168.1.32:8080).

- If you can now access this web page, the controller does have a wireless connection, so its access point is not on.

- Here you can control the unit's MQTT settings, and change the WiFi settings as well. You can change and save the access point, or just restore the defaults to erase it.

- If it doesn't work, restart or power cycle the controller to start over.

Test the MQTT Reporting

Although the ESPlorer console displays the controller status, when deployed, the controller gets its power from the original controller +5v rail, not the usb.

- Do not connect the USB to a powered on trap. The results are unpredictable, and not good. You may damage your PC or the original controller, or who knows what? You may have to remove the controller from the trap to use the usb connection.

- Open mqtt-spy and create a connection to whatever mqtt server was specified on the controller web page. Subscribe to the specific topic configured. You should see your data stream match the info on the console.

- You can configure mqtt-spy to save a log file, with size rotation, etc. This is very helpful to troubleshoot problems over several days worth of operation. You will need an editor (e.g., notepad++) that can open a large text file, and update the file as new data is appended.

- Open your phone's MQTT client (e.g., MQTT Snooper), connect, subscribe, and observe the data stream.

When you have all of this working, you can continue to building the wiring harness, modifying the controller, and installing the Add-On.

Build the Wiring Harness

- Cut a 40 or so pin 100 mil female header down to 15 pins. Sand the cut edge so you don't get injured.

- Cut appropriate lengths of colored wire. The initial prototype shown here might have the wires a tad short. The Add-On should not suffer from tight wires. The prototype wires were a little too short. The signals are not critical, a little extra length will not hurt.

- Solder one end of each wire to the appropriate pin on the header. Your colors may differ from these:

| position | color | net | destination |

|---|---|---|---|

| 16 | orange | 3.3v | HTU21D '+' |

| 17 | white | ground | HTU21D '-' |

| 18 | brown | LED | R2 and PIC #1 |

| 19 | n/c | n/c | n/c |

| 20 | yellow | Gas | R10 and PIC #8 |

| 21 | violet | switch | J1 pin 1 |

| 22 | blue | FAN | via & PIC pin 7 (delicate!) |

| 23 | green | thermlo | R5 |

| 24 | white | ground | J1 pin 2 |

| 25 | orange | 3.3v, VDD | J1 pin 3 |

| 26 | yellow | sdl | HTU21D SDL |

| 27 | violet | sda | HTU21D SDA |

| 28 | n/c | n/c | n/c |

| 29 | red | Ign | PIC pin 6 (delicate!) |

| 30 | brown | LED | R2 and PIC #1 |

Unlike the prototype, each wire should be insulated and strain relieved.

You can use another 15 pin connector, but it is easier to use a 2 pin and 1 pin header (although you must never flip the 2 pin header).

| position | color | net | destination |

|---|---|---|---|

| 1 | white | adc & tock1 | R5 low side to thermister |

| 2-13 | n/c | n/c | n/c |

| 14 | white | ground | C6 - |

| 15 | orange | Vin +5v | C6 + |

Modify the Controller PCB

To restore the original controller, these steps must be undone. Do them carefully with an eye to eventual restoration.

- Make sure the tank is outside.

- Cut the foil to C4 near R5 and R6

- Unsolder and use a thin gauge needle or syringe to carefully pry and slightly lift PIC pin 4 from its pad on +5v, then solder a very thin (e.g., 40 gauge) 1 strand jumper between the lifted pin and the adjacent pin #5 (ground). This sets the MCLR/ signal low, which effectively disconnects the PIC (according to the spec, not tested). The alternative is to remove the PIC completely (not recommended).

- Solder a jumper wire between pin 14 and the top of R5 or pin 11. This connects VDD to R5 20k0.

- Locate and cut the foil on the bottom of the PCB connecting VDD to +5v to create the new net +5C, which will be fed 3.3 volts from the NodeMCU.

Attach the Harness

Carefully solder the harness wires to the strongest terminals first, then end up on the most delicate.

- The right hand white and orange wires connect to the original ground and +5v rails near the electrolytic cap. It might be better if they were longer and attached to the PCB bottom to the through hole electrolytic cap, but this connection seems ok.

- The single pin white wire connects the ADC input to the bottom of R5.

- Strain relieve the two most delicate connections to prevent ripping up the foils.

Install Modified Controller into Trap

- Make sure the propane tank is outside and off.

- Disconnect the usb and connect the NodeMCU module to the headers. Connect the HTU21D.

- Connect the igniter, fan, valve, solenoid, switch, and plug the trap into the power. The fan will briefly spin. After 5 seconds, the fan will turn on and the LED will start to blink.

- Observe the unit using mqtt-spy. Read the thermistor temperature. It should be close to the external temperature.

- Observe the unit progress the ignition start, and check that the fan, igniter, and valve solenoid all work in sequence. The unit will fail to start without propane connected. Observe the unit going into the error state (7) after several minutes.

Move Trap to Operating Location

- Move the trap outside, connect the propane, observe the data stream on your phone using an MQTT client.

- Observe trap startup. With the top cover off, you may have to block much of the fan using a piece of paper to reduce the air flow to get a combustible air-fuel mix.

- The trap should reach 100°C and higher.

Final Test

- Remove the paper, and place the cover over the trap, taking care to not crush any wires, or knock the Add-Ons. Install an empty catch basket.

- If it seems Ok, go inside and let it run. Prepare a fresh attractant cartridge for your trap. Put it in.

Monitor from PC and Phone

- Refine your mqtt client configuration to save log files, record only one unit, etc.

- If the unit fails (internal temperature drops to under, say, 90°C), open the log file and find the time this started, then develop a theory as to why this happened, and take a corrective action, and try again. Repeat as necessary.

Post your findings on the forum. Welcome to the club!

System Requirements

To be written.

System Design Description

To be written.